Artificial plant lighting on shelving systems

Modules LED FARM

DATA SHEET

Design

Housing

Made from high quality aluminum.

Safety glass

Manufactured from UV stabilized optical polycarbonate.

LEDs

High-efficiency energy-saving LEDs manufactured by

Seoul Semiconductor (South Korea)

Side covers

Made from durable polymer material.

Fastening

Modules are supplied with fastening elements:

hardware / corners / brackets.

LED FARM modules have two design versions that differ in the input (output) of the supply wire. In the module designation:

X = 1 – the module has only an input wire;

X = 2 – the module has an input and output wire.

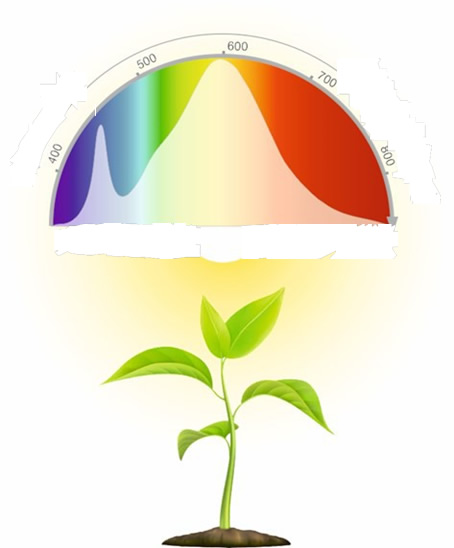

LED FARM 40.1.1 / LED FARM 80.1.1

LED FARM 40.1.2 / LED FARM 80.1.2

Technical parameters

| Parameter name | LED FARM 40.1.X |

LED FARM 80.1.X |

| Input current direct (DC), A | 1,4 | 1,4 |

| Input voltage, V | 28 | 56 |

| Power consumption, W | 39 | 78 |

| Radiation flux, W | 19 | 38 |

| Photon flux, µmol/s | 92 | 184 |

| Luminous flux, lm | 6250 | 12500 |

| Energy safety class | A+ | A+ |

| Degree safety | IP65 | IP65 |

| Operation temperature range, 0C | +1…+40 | +1…+40 |

| Weight, kg | 0,6 | 1,2 |

| Dimensions, mm | 585х55х40 | 1160х55х40 |

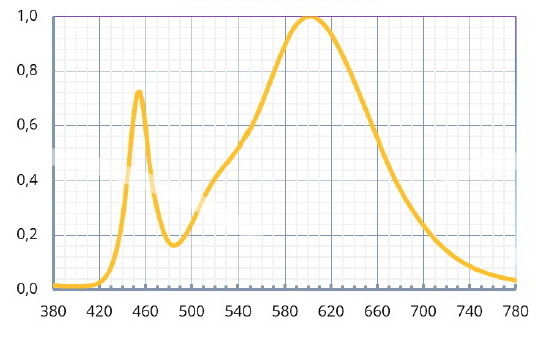

Emission spectrum

FLORA LED modules are a source of optical radiation in a wide range of wavelengths, including in the range of photosyn- thetic active radiation, ensuring the course of the whole variety of photobiological processes inherent in plant organisms.

The nominal service life of the modules is 10 years with reliability indicators L90F10 ≥ 60000 hours

( IEC/PAS 62717:2011).

Warranty period of operation – 36 month.

Installation

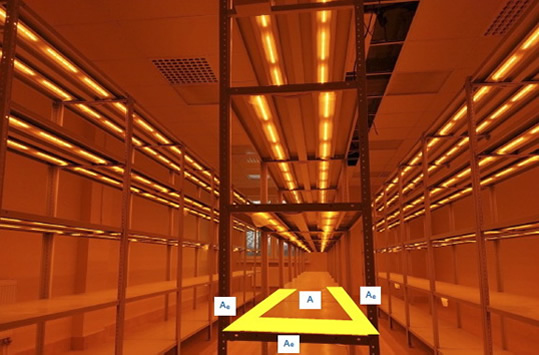

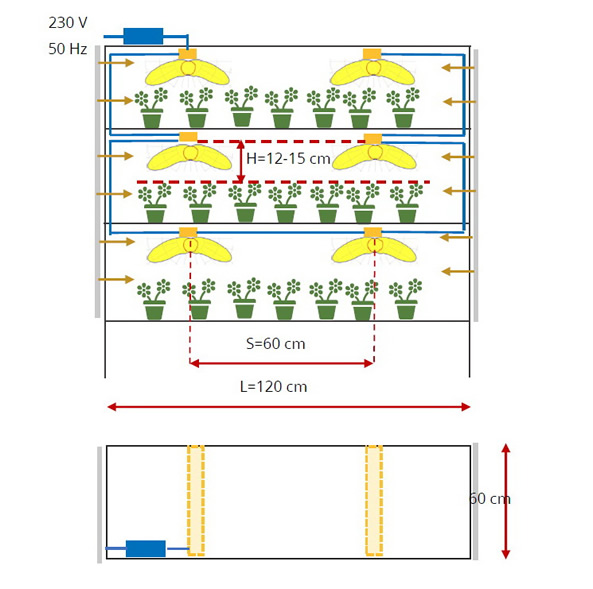

Transverse arrangement of modules

Longitudinal arrangement of modules

To create the energy efficiency of shelving lighting system, it is recommended to place the modules in the transverse direc- tion of the shelves. In this case, the specific gravity of the edge zone Ae in the zone of plant A growing is reduced. This arrangement of modules is also more convenient for maintenance and repair of lighting equipment.

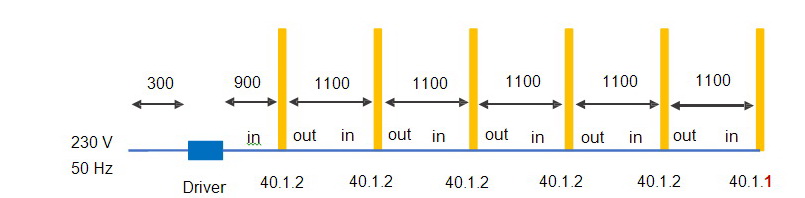

LED FARM modules are connected in series into an electrical circuit between themselves and connected to an external power supply network through an AC – DC power source (driver). It is recommended to use power supply type XLG-240- M-A or XLG-240-M-AB (if you need to implement control via an industrial controller using the 1-10 V protocol). An optimal electrical circuit is recommended, including: 1 pc power supply XLG-240-M-A (AB) and 6 modules LED FARM 40.X.X or 3 modules LED FARM 80.X.X modules. The length of the connecting wires in mm in the basic delivery variant (default) is shown in the figure:

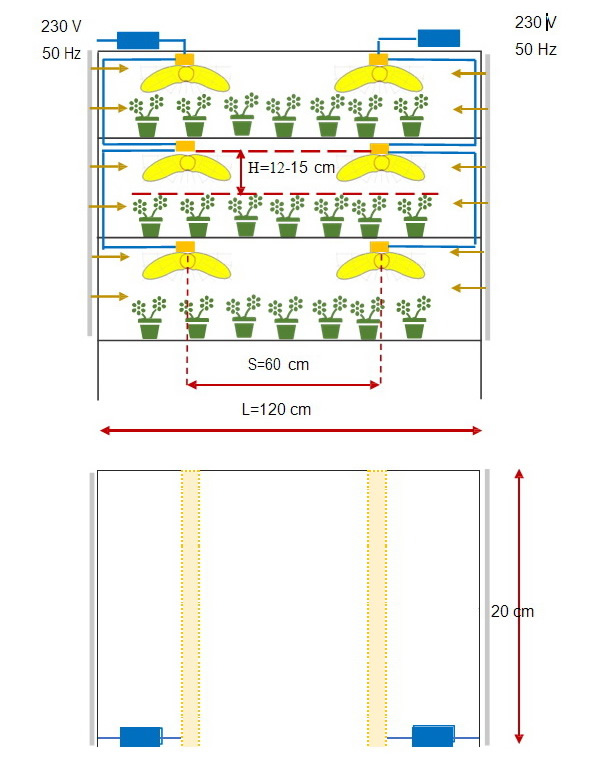

Along the length of the shelving, the luminous intensity curve of the modules is wide. The light is distributed in the hori- zontal plane already at a distance of 12-15 cm from the protective glass of the modules. Therefore, it is recommended to place the modules at a distance of about 15 cm from the tops of the plants. In order to avoid light losses, it is recom- mended to use reflective elements on the end sides of the end shelving of the production line.

The recommended distance between the modules (spacing) is S = 60 cm.

For a shelving module with 3 shelves with a length of 120 cm and a width of 120 cm, it is recommended to use 6 modules

LED FARM 80.1.X. and 2 driver Mean Well XLG-240-M-A (or XLG-240-M-AB). The power supply is located on top of the shelving. Connecting wires are located along the supports and shelves.

For a production line equipped with LED FARM modules with an interval of 60 cm, we obtain the average horizontal irradi- ance of the plant growing area at a distance of 15 cm from the protective glass of the module Ep = 200 µmol/m2•s. The specific installed power on the production line equipped with LED FARM modules will be ≤ 120 W/m2.To reduce the influ- ence of edge zones, it is recommended to design production areas with light walls and install production lines at a short distance from each other. The superposition of the rays of a large number of light sources leads to an increase in the uni- formity of irradiation of plants.

| (150 ± 20%)

µmol/m2•s |

(180 ± 5%) µmol/m2•s | (150 ± 20%)

µmol/m2•s |

| (210 ± 5%) µmol/m2•s | ||

| (180 ± 5%) µmol/m2•s |

For a shelving module with 3 shelves with a length of 120 cm and a width of 120 cm, it is recommended to use 6 modules

LED FARM 80.1.X. and 2 driver Mean Well XLG-240-M-A (or XLG-240-M-AB).

General recommendations for DLI

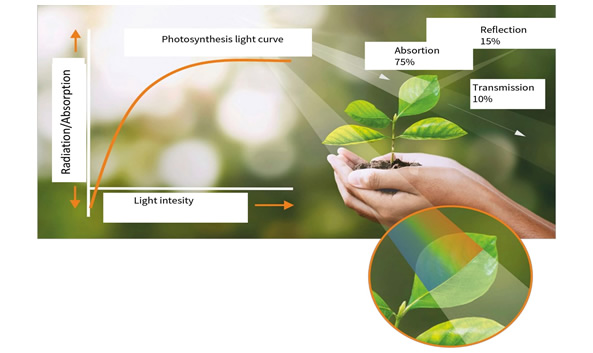

The intensity of photosynthesis strongly depends on the irradiance of the phytocenosis of photosynthetic active ra- diation (photosynthetic irradiance). This dependence is expressed by a logarithmic curve, called the light curve of photosynthesis.

There are three characteristic sections of the photosyn- thesis curve:

01 Straight section up to irradiance level 100…150 W/m2 or 500…750 µmol/m2•s PAR (20000…30000 lx). In this area, the rate of photosynthesis increases in proportion to the increase in irradiance.

02 Curvilinear section up to irradiance level 250…300

W/m2 or 1250…1500 µmol/m2•s PAR (50000…60000 lx). In this area, the rate of photosynthesis slows down, but con- tinues to increase, although not in proportion to the in-crease in irradiance.

03 Straight section. In this area, a further increase in irra- diance does not cause a change in the rate of photosyn- thesis. The latter state is called the state of light saturation. In plants of the temperate zone, light saturation occurs at an irradiance of 100…200 W/m2 or 500…1000 µmol/m2•s PAR (20000…40000 lx).

The following optimal standardized irradiance in the greenhouse is recommended:

40 W/m2 (180 – 200 µmol/m2•s) PAR with a photoperiod of

14 hours when growing seedlings;

100 W/m2 (450 – 500 µmol/m2•s) PAR with a photoperiod

of 16 hours when growing plants for production.

In this case, the optimal daily amount of irradiation (dose) for seedlings will be 560 W•h/m2 (2.0 MJ/m2•day or 9–10 mol/m2•day), and for growing plants for production – 1600

W •h/m2 (5.8 MJ/m2•d or 26 – 29 mol/m2•d).

General recommended levels of plant irradiation and daily dose of irradiation

| Plants | DLI (Daily Light Integral) | PPFD | ||

| MJ/m2 | mol/m2 | W/m2 | µmol/m2 •s | |

| Micropropagation of plants | 0,5 – 1,0 | 2,5 – 5,0 | 10 – 20 | 50 – 100 |

| Microgreens, green crops, seedlings | 1,0 – 2,0 | 5,0 – 10,0 | 20 – 40 | 100 – 200 |

| Berry crops | 2,0 – 4,0 | 10,0 – 20,0 | 40 – 80 | 200 – 400 |

| Vegetable crops (tomato, cucumber, pepper) | 4,0 – 8,0 | 20,0 – 40,0 | 80 – 120 | 400 – 600 |